ENVIRONMENTAL PROTECTION THROUGH EFFICIENT USE OF RESOURCES.

The sustainable improvement of environmental and climate protection is one of the greatest challenges of our time. We develop pioneering processes for the processing and recycling of residual and waste materials. Our clients are construction companies and the public sector in Germany and Europe. Our services include consulting, planning and implementation of projects for the analysis and use of soils and excavated materials, the immobilization of pollutants and the production of sustainable substitute building materials. We also carry out geotechnical soil and contaminated site investigations for our clients.

With 30 years of experience, our own production facilities and our research center at the Bremen site, we are a highly specialized provider of solutions for the increasing demand for technically sophisticated substitute building materials.

SUSTAINABLE IMMOBILIZATION OF POLLUTANTS AND INNOVATIVE SUBSTITUTE BUILDING MATERIALS.

The conservation of natural and limited resources, such as sand and clay, is becoming increasingly important in the production of building materials. As experts in the immobilization of pollutants and the production of substitute building materials, we use innovative processes for the efficient recycling of residual materials, for example from the processing of sediments, slag and excavated material from construction sites. By adding natural additives, we produce sustainable and specific products on an industrial scale in our in-house production facility.

Our processes and products are developed to patent maturity and are subject to constant quality control. By using our mobile mixing plant with a capacity of up to 1,000 cubic meters/day, we are able to implement projects with corresponding volumes for our customers.

SPECIALIZED GEOTECHNICAL ENGINEERING SERVICES.

Our geotechnical engineering office offers special geotechnical soil investigations, contaminated site investigations and assessments as well as advice on professional waste management. We are experts in our field — our clients are happy to rely on our knowledge.

Our employees are highly specialized, competent and always keen to develop extraordinary ideas to protect the environment. Are you a student and environmental protection is your mission? We offer internships and dissertations to students of engineering and natural sciences.

Different applications for substitute building materials require specific, application-dependent product properties such as strength, permeability and long-term stability.

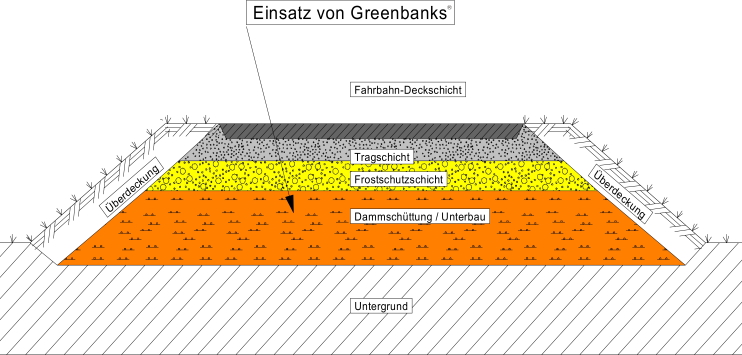

In the production of Greenbanks® , mineral recyclates and residual materials are added to the basic formulation, resulting in a significantly improved load-bearing capacity. This results in various possible applications for Greenbanks®, for example as an embankment material in road construction or as a sand substitute in earthworks.

GREENBANKS® IN ROAD CONSTRUCTION AND AS BACKFILL FOR INDUSTRIAL AREAS

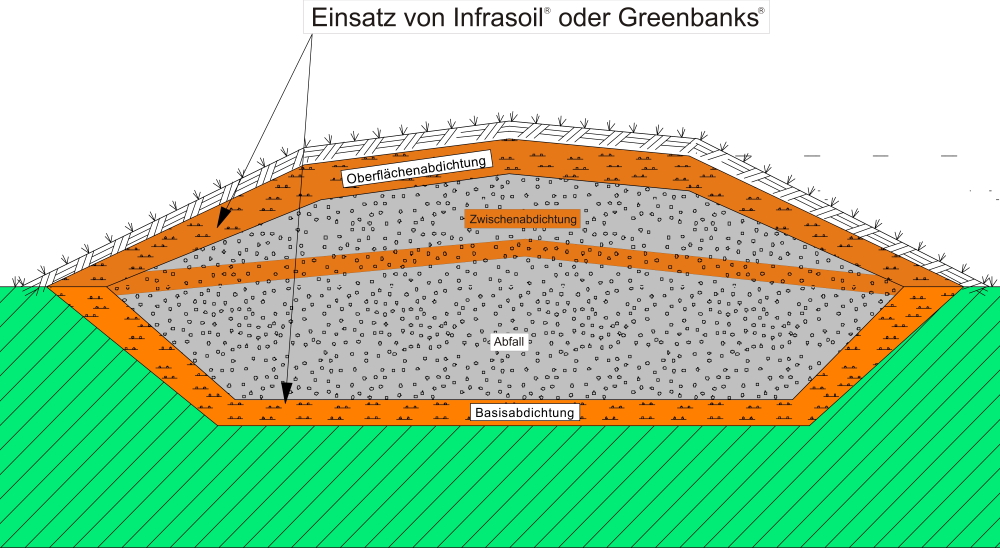

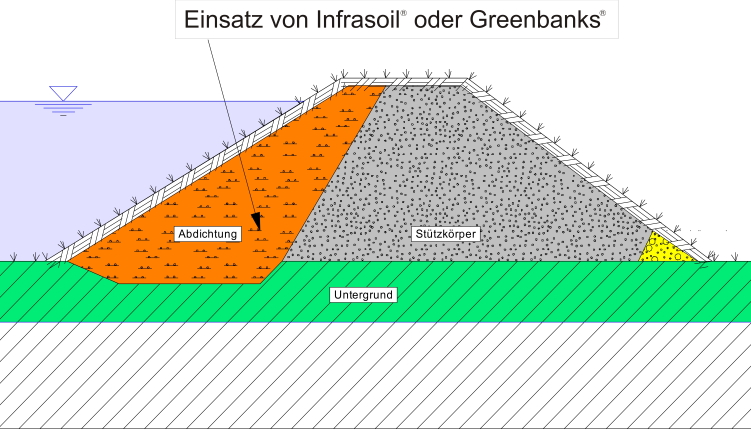

The basic formulation of Infrasoil® is based on separated clay minerals and special natural additives that are added to soils and sediments. Infrasoil® is ideally suited as a mineral sealing material for the construction of dykes, landfills, artificial ponds and drainage fields.

INFRASOIL® AS A MINERAL SEALING MATERIAL IN LANDFILL CONSTRUCTION

INFRASOIL® IN DIKE CONSTRUCTION

The use of Infrasoil® and Greenbanks® is worthwhile from a construction and environmental point of view. In accordance with the Closed Substance Cycle Waste Management Act, it is necessary to recycle soils and sediments instead of disposing of them. This saves valuable resources as the natural building material is not extracted elsewhere. The environment is spared the consumption of land and natural resources caused by extraction and the CO2 emissions caused by transportation. This is especially true if the material is reused and recycled on site.

QUALITY ASSURANCE OF OUR PRODUCTS: INDEPENDENCE AND DIVERSITY OF TESTING

Our building materials Greenbanks® and Infrasoil® have been tested by independent institutes, including the Geodelft Institute, the University of Braunschweig and the Leuphana University of Lüneburg. The physical and environmental-chemical properties of the building materials, the relationship between the functionality of the material and the design specifications and the long-term durability (> 80 years) were examined.

Dredged material from sediment deposits in bodies of water that is removed to maintain shipping operations must be dewatered for further use or disposal.

The required dewatering takes place on special drying fields, into which the dredged material is rinsed after removal. The drying time can be significantly reduced by adding biological flocculants. This significantly increases the capacity of the dredging field and reduces the need to build new dredging fields. This innovative dewatering process is constantly being further developed at our research center.

The development and testing of pioneering technologies takes place in our in-house research center. This includes laboratories for geotechnical and biological analyses, a greenhouse for plant experiments and open areas for large-scale tests with professional mechanical equipment. We work on various key topics here, both in-house and in cooperation with universities and other research institutions.

Our research focuses:

- Resource-conserving building materials and substrates

- Landfill and earth building materials made from recycled material

- Peat alternatives in plant substrates

- Testing innovative processes for faster drainage in drying fields through the use of environmentally friendly flocculants

MEMBERSHIPS

- DWA German Association for Water, Wastewater and Waste e.V.

- PUU Partnerschaft Umwelt unternehmen, Bremen

- BU Construction monitoring association for environmental protection

- RWB Forschungsvereinigung Recycling und Wertstoffverwertung im Bauwesen e.V.

CERTIFICATES

- ISO 9001

- ISO 14001

- ISO 45001

- Waste management officer in accordance with § 54 KrWG, § 9 EfbV and § 5 AbfAEV

- Sampling according to LAGA PN 98

ONGOING PROJECTS

REFERENCES

GROUND INVESTIGATIONS IN THE NEW COFFEE QUARTER

Project end 2022

CONSTRUCTION OF A ROAD EMBANKMENT (NL)

Project end 2006

INTEGRATED DREDGED MATERIAL DISPOSAL SYSTEM

End of project 2003

Contact us

DETLEF HEGEMANN Umwelttechnik GmbH

E umwelttechnik@hegemann-reiners.de

BREMEN

Arberger Hafendamm 16 | 28309 Bremen

T +49 421 4107–0 | F +49 421 4107–299