Client: Stuttgarter Straßenbahnen AG

Project author: PSP Consulting Engineers GmbH, Munich

Construction work: Roofing U12 3.TA Hallschlag — Aubrücke

Partners: Leonhard Weiss GmbH & Co. KG | Bauer Spezialtiefbau GmbH | AUGUST REINERS Bauunternehmung GmbH

Tech. Management: Leonhard Weiss GmbH & Co KG

Commercial management: AUGUST REINERS Bauunternehmung GmbH

Object: Light rail line Stuttgart U12 3rd section Hallschlag — Aubrücke

Period: 2013 to 2017

The 3rd section of the U12 light rail line comprises the realignment of the section from Hallschlag to the Aubrücke bridge. It begins directly after the Hallschlag stop (transition from the 2nd section to the 3rd section) and initially runs along Löwentorstraße, passes under the freight bypass and ends at the southern abutment of the Aubrücke bridge where it joins the existing network. The subsoil has a rapidly changing and very varied structure: The first few meters consist of artificial fill everywhere, followed by locally heterogeneous silt/sand mixtures. In the area of the old “Kleines Feldle” landfill, there was also a clay pit whose fill (at least 15 m thick) consisted largely of excavated building pit material, quarry spoil, building rubble and waste. Adjacent to the clay pit to the north-east was a quarry where travertine was quarried in the past. The backfill of the quarry also consists mainly of overburden material.

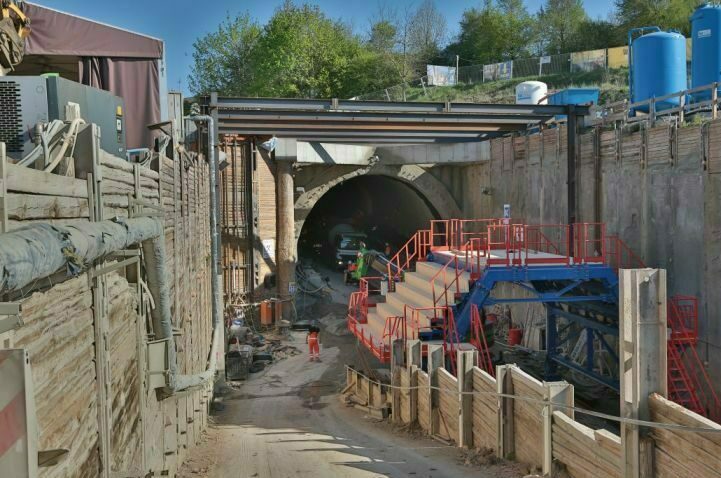

The 200 m long tunnel section was built using the mining method. The double-track standard cross-section has a clear width of 9.20 m and a clear height of 7.43 m. The inner shell of waterproof concrete is also 40 cm thick. The mined tunnel was excavated from an open excavation pit in the area of the northern tunnel section, ascending in a southerly direction. The stop was protected by a bored pile wall. In the course of the drive, the railroad embankment of the DB line 4720 Untertürkheim — Kornwestheim was crossed underneath with an overburden of 8.00 — 10.00 meters. Furthermore, the entire mined tunnel was built using a closed construction method with a vaulted cross-section.

Driving and support were also carried out using the shotcrete construction method; the drive was carried out in partial cross-sections as an elm tunnel drive. The main support elements were reinforced shotcrete and steel support arches; in addition, due to the relatively unfavorable ground conditions, spiles and pipe umbrellas were used as advance support. In addition, the face was secured using shotcrete and face anchors. In the area of the stop wall, a pipe umbrella was inserted from the excavation pit, and a Carinthian cover was installed in the area of the cut-through wall.

TECHNICAL DATA

Structural function: Underground tunnel

Tunnel length: 200 m

Excavation volume: 15,400 m³

Construction method: Shotcrete construction method (excavator drive)

Tunnel support: pipe umbrellas, anchors, support arches, shotcrete

Special features: Elm tunnel drive in several partial windows